- Galvanized color coated

- galvanized coil

- color coated coil

- PPGI

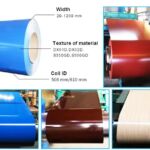

The production method of color coated coil is: on a continuous unit, cold-rolled strip steel and galvanized strip steel (electric galvanizing and hot dip galvanizing) are used as the base plate.

After surface pretreatment (degreasing, chemical treatment), one or more layers of liquid coating are applied by rolling coating method, and the sheet obtained after baking and cooling is coated steel plate.

Because the coating can have a variety of colors, the coated steel plate is usually called a color coated steel plate.

Because the coating is carried out before the steel plate is formed and processed, it is also called pre-coated steel plate.

The process flow of color coated steel coil is: color coated steel plate is cold-rolled steel plate and galvanized steel plate as the base material, after surface pretreatment (degreasing, cleaning, chemical conversion), continuous coating (rolling coating method), baking, cooling products.

Color coated Coil recommended click here

Color coated coil is called color coated coil or color coated steel plate in daily life.

The product is continuously degreased on the surface of the steel strip by chemical conversion process such as phosphating on the production line, and then the steel coated with organic coating is brought into ICBC to bake at high temperature.

Generally speaking, the surface color of this steel plate is more vivid than the surface color, and we also call this steel plate color coated roll and color coated plate.

For the use of color coating rolls, we must choose different types of color coating rolls to manufacture different products.

According to the use of household appliances, optical materials, decorative materials, building materials and packaging five categories.

.jpg)